How 3D printing will change the world

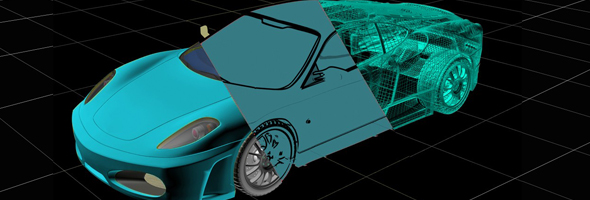

3D Printing, or additive manufacturing, is the process of making a three-dimensional object from a 3D model or other electronic data source. Primarily through additive processes, successive layers of material (liquid, powder, paper or sheet material) are applied under computer control using a 3D printer (a type of industrial robot). 3D printable models can be created with a Computer-Aided Design (CAD) package or a 3D scanner. Industrial applications for 3D printers include rapid prototyping, rapid manufacturing, mass customization and mass production.

3D Printing is moving in several directions at this time and all indications are that it will continue to expand in many areas in the future. Some of the most promising areas include medical applications, custom parts replacement, and customized consumer products. As materials improve and costs go down, other applications we can barely imagine today will become possible.

Dream & Designs Convert to Reality

In the modern boom of digital art and design, the possibilities are not only accelerating but limitless. One can now 3D print almost anything they imagine after drawing it up virtually. In a relatively short time, an idea, concept, dream or invention can go from a simple thought to a produced part that you can hold.

Effect

Companies will no longer have to store inventory of products or even manufacture and distribute them anymore. The idea of ‘seasons’ for products would disappear, as every product ever made would be forever available as a downloadable file. No more discontinued items, and no more waste, as old products could forever be repaired and reused.

This ability to ‘forever repair’ products has obvious negative repercussions for businesses. What better motivator for buying a new product than having your old product break? I suppose the race is on to build ‘better products’ in order to encourage consumers to upgrade to the latest offering, since repairing the old products will be so simple and accessible.

Future Scope

3D Printing is moving in several directions at this time and all indications are that it will continue to expand in many areas in the future. Some of the most promising areas include medical applications, custom parts replacement, and customized consumer products. As materials improve and costs go down, other applications we can barely imagine today will become possible.